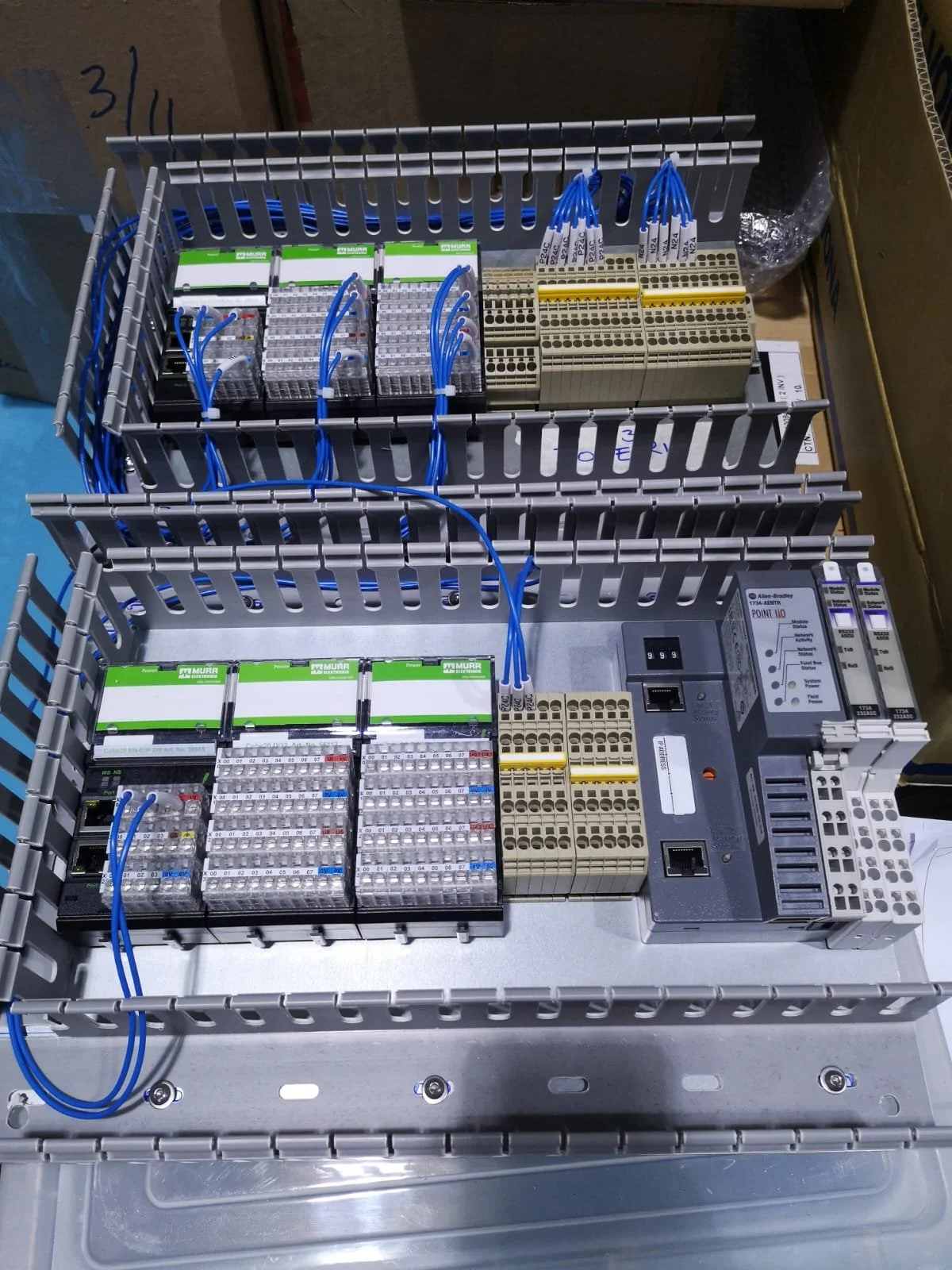

Past Projects

Comissioned Date: Feb 2021

Design Pressure Of System: 2,900psi / 200Bar

Operating Pressure: 72.5bar / 5Bar

Media: H2, CH4 & N2 Gas

Application: Calibration of data loggers and digital measuring meters.

The Requirement: In the event of H2 or CH4 gas leak, customized control panel must be able to detect the before mentioned gas. Once gas leak was detected, an alarm will sound to warn the people within the premises. The pressure within the control panel must be able to purge pressure out of building automatically. The system can be depressurized by turning off the alarm at the control panel.

Customized Gas Detector System Come With Control Panel & Gas Cage For H2, CH4 & N2 Gas

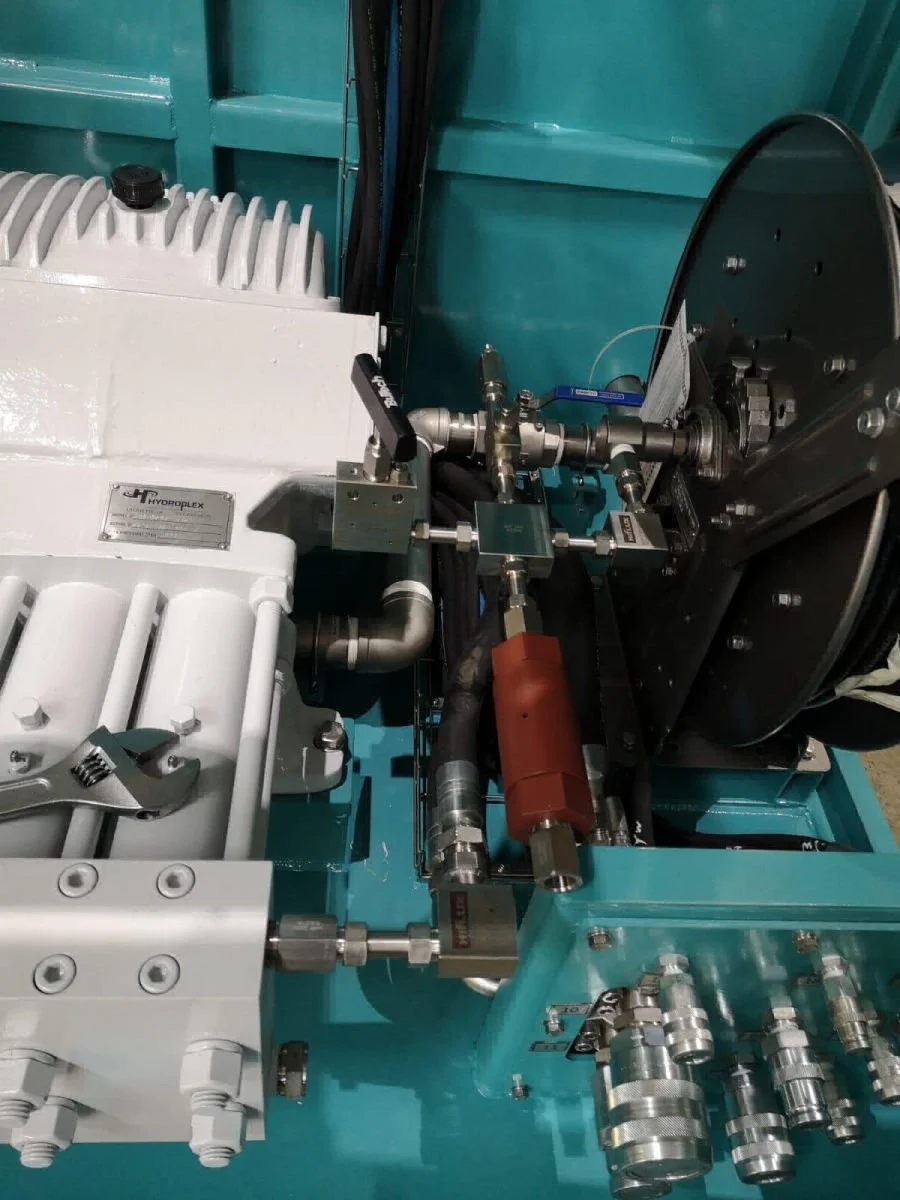

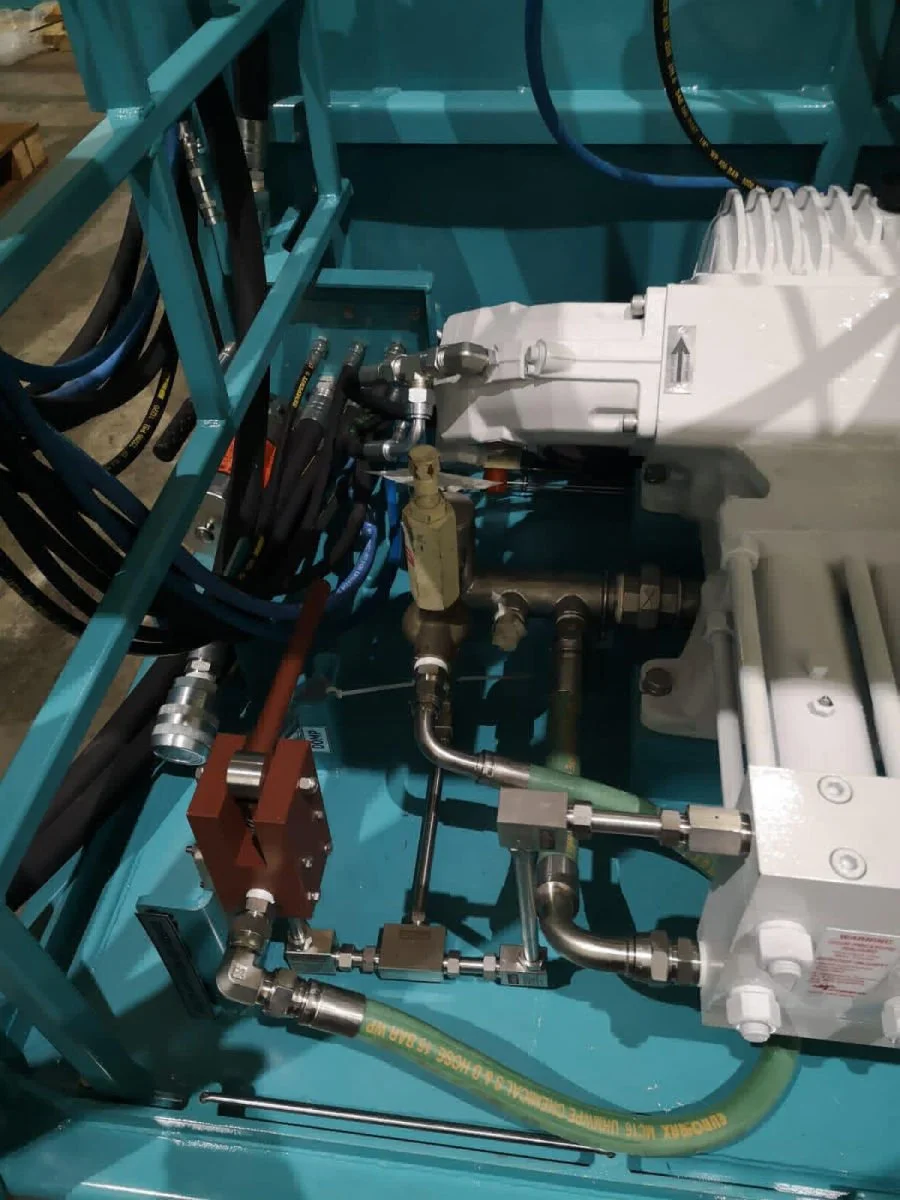

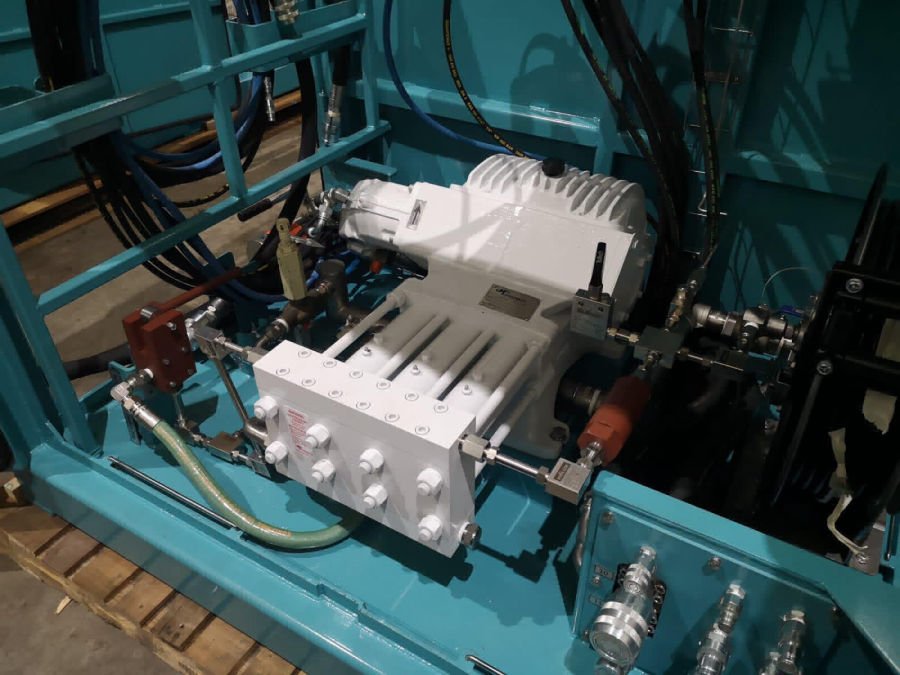

Comissioned Date: November 2020

Design Pressure Of System: 15,000psi / 1,034Bar

Operating Pressure: 10,000psi / 700Bar

Media: Hydraulic Oil

Application: Triplex Pump Flushing Unit

The Requirement: Client's existing Triplex Pump can go up to pressure as high as 15,000psi potentially. Triplex Pumps also produces high flow rate and based on client's engineer, the smallest tubing size they can accept is 1/2" OD. Due to this requirement, none of the standard seamless tubing in the market are able to withstand such high pressure. The solution we propose was to install autoclave 9/16" tubings on their existing flushing unit.

Installation Of Medium Pressure 9/16" Tubings On Triplex Pump

Customized Portable Hydrotest Unit c/w Castor Wheels

Comissioned Date: July 2020

Design Pressure Of System: 850psi / 60Bar

Operating Pressure: 850psi / 60Bar

Media: Water

Application: Pressure testing of various valves.

The Requirement: Client request that we built something which is portable and easy to manoeuvre as they plan to have the hydrotest unit at site to conduct pressure testing on a regular basis. In addition to the weight, they also require the hydrotest unit to have 2 outlet ports. One to be able to test up to 850psi (High Pressure Port). The other to be able to test up to 35psi (Low Pressure Port).

Modification Of Air Testing System

Commissioned Date: June 2020

Design Pressure Of System: 250psi / 17Bar

Operating Pressure: 200psi / 14Bar

Media: Industrial Air

Application: Pressure testing of semiconductor components

The Requirement: Client's original air testing unit is capable of testing multiple ports of pressure up to 100psi only. They decided to upgrade their system to have additonal ports which will be able to test pressure up to 200psi. The booster we added for the client will be able to meet that requirement and at the same time not affect the air flow which will test 100psi as it runs on it's own air inlet supply pressure.

Contact us

Hydromax Automation And Engineering Pte Ltd

(Reg No.: 202112689K)

Email: sales@hydromax.com.sg

Address: 280 Woodlands Industrial Park E5, #10-26, S757322